The major scientific and technical works of Prof. D'Abreu has significantly contributed to the establishment and development of various metallurgical processes, particularly for ironmaking and non-ferrous technologies, residues recycling and effluents treatments, and energy efficiency implementation in a large number of materials processing and their related reduction of CO2 emission, ever focusing sustainability as one of the main research and cooperative industrial projects outputs. In Brazil Prof. D'Abreu has dedicated himself to the academic activities of research and education in Pontifical Catholic University of Rio de Janeiro (PUC-Rio) and as conferee Professor in Military Institute of Engineering (IME) and Fluminense Federal University (UFF). With more than 250 papers published in Journals and Proceedings, 2 books issued, 60 MSc and PhD academic advisory and more than 1500 graduate students taught in several disciplines in courses such as metallurgy, materials, mechanics and chemical engineering, he has been considered an "all-in-one" Professor. Passionate, motivated, oriented for practical results, visionary and a systematic thinker, he continues to inspire worldwide generations of engineers and students. In a list far from being exhaustive, Prof. D'Abreu has a significant number of ex-students in senior positions at private Companies, Universities and Government Departments in Brazil and other countries. Devoted to the field of engineering processing of materials and their environmental and social implications, many achievements can be credited to Prof. D'Abreu along his still current operative life , such as:

Eager to learn more about the materials processing developments, Prof. D'Abreu participates in many congresses, conferences and meetings, ever accessing several other sources of knowledge, in order to share and discuss the latest activities with students, industry professionals and colleagues throughout the world. As a very active member in scientific and technical world associations, like ABM, AIST, TMS and APMMM, he has served and helped their growth. He actively occupied various managerial positions in the Brazilian Association of Metallurgy, Materials and Mining - ABM, where worked as a leader in important research projects for the govern and private industries and also personally leading efforts for books publication, technical courses, creation of technical divisions, interfacing with the industry and pushing students to participate in the association. Currently he is a member of ABM Institute Pro-Innovation and Competitiveness - IABM, where he was a President for 4 years and directly supervised the strategic governmental study: "Prospective Study of the Brazilian Steel Industry in 2025". Regarding the "Associacion Peruana de Metalurgia, Materiales y Mineracion - APMMM", he encouraged and founded the association with some Peruvian PhD ex-students, receiving an Honorific title from this association. As a permanent member of the "Forum for Steel Industry Competitiveness" from the Ministry of Development, Industry and Commerce - MDIC , he has assisted the govern with diagnostic reports, trends programs, action plans and debates. In 2012, as major Chairman, he was directly involved in bringing the "6th International Conference on Science and Technology of Ironmaking - ICSTI", to Rio de Janeiro. This important conference gathered experts of industry and academia, from more than 50 countries. Currently Prof. D'Abreu is also a member of the Scientific and Technical Council of the National Mineral Technology Center - Cetem, one of the 17 Research Institution of the Brazilian Govern. Through these lifetime achievements, his contribution to the advancement and improvement of materials processing engineering field has been effectively significant and recognized by Academia and Industry.

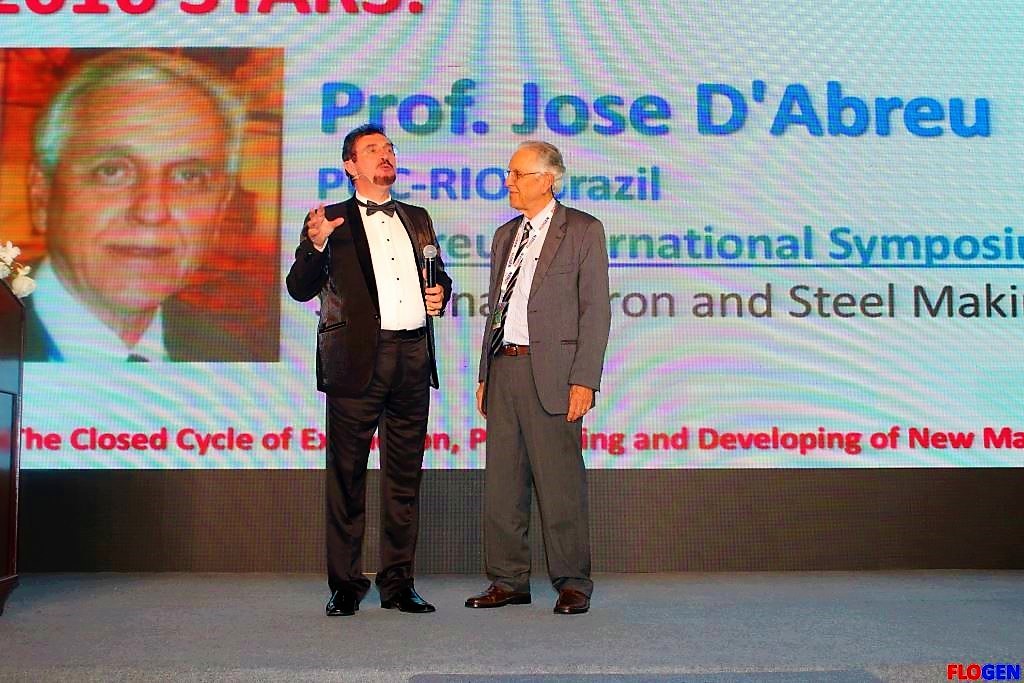

Prof. Jose D'Abreu, Receiving the Fray International Sustainability Award from Dr. Florian Kongoli at FLOGEN SIPS 2016

Dr. Florian Kongoli introducing Prof. Jose D'Abreu as a winner of Fray International Sustainability Award at FLOGEN SIPS 2016

Prof. Jose D'Abreu delivering his acceptance speech to Dr. Florian Kongoli, during the FLOGEN SIPS Fray International Sustainability Award ceremony

Prof. Jose Carlos D'Abreu receives FLOGEN SIPS 2016 Fray International Sustainability Award given to him by Dr. Florain Kongoli

SIPS 2018 - INTERVIEW WITH PROF. JOSE CARLOS D'ABREU

FLOGEN SIPS 2016 Awardees: Prof. Jose Carlos D'Abreu in conversation with Dr Florian Kongoli